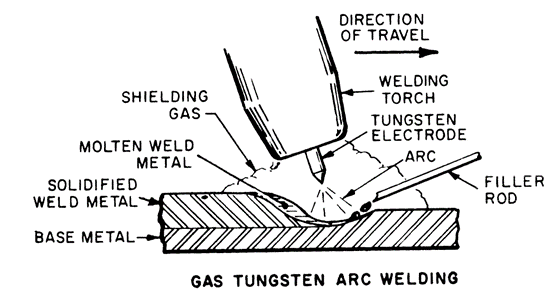

An arc welding process which produces coalescence of metals by heating them with an arc between a tungsten (nonconsumable) electrode and the work. Shielding is obtained from a gas or gas mixture.

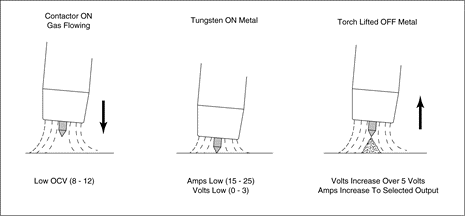

Lift Start was developed to provide a positive means of starting the Gas Tungsten Welding arc without high frequency. High frequency energy has been a very effective method of initiating the arc, but in some cases interferes with computerized equipment. In an effort to solve this problem, other means to start the arc were needed. Capacitor discharge circuits have been used, but they also produce radio frequency interference. Also, both high frequency and capacitor discharge circuits are limited to relatively short torch lead lengths.

Lift Start GTAW is not the same as “Scratch Tig”’ which results in rapid deterioration of the tungsten. Lift Start works quite differently. Lift Start circuitry permits the tungsten electrode of the GTAW torch to be placed precisely at the start of the weld, without damage to the tungsten or base metal. When the tungsten contacts the metal, the power supply limits it’s output to a very low preset value. The welding arc does not come on until after the tungsten is withdrawn from the metal. The power supply then automatically adjusts it’s output to the selected welding amperage. Lift Start may be used with AC or DC operation and may be used with torch leads up to 25ft.

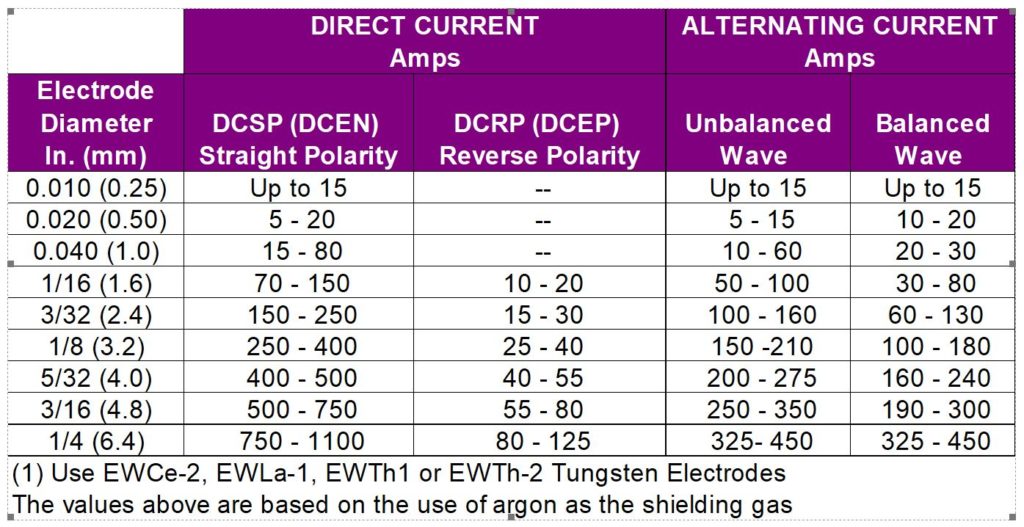

Connect the TIG torch to the – / TORCH terminal and the work lead to the + / WORK terminal for direct current straight polarity. Direct current straight polarity is the most widely used polarity for DC TIG welding. It allows limited wear of the electrode since 70% of the heat is concentrated at the work piece.