Generator power vs mains power

Compared to mains power, generator power can be characteristically ‘dirty’ and thus has the potential to damage sensitive electronic components inside inverter welding machines. This is especially the case with smaller generator sets that are often chosen for operating the likes of power tools and welders, due to their portability and affordability.

At the same time, the ability to use generator power offers many advantages to operators wanting to run their inverter welding machines in the field or on-site where it is impossible or difficult to access mains power.

So, it is no surprise that one of the first questions operators ask before they consider purchasing an inverter welding machine is: “is it safe to run off a generator?”. The truthful answer is not always a “yes”. Sure, plug virtually any inverter welder into a generator and it will likely operate to some level. But not all generators are created equal and have clean power.

Why is generator power potentially harmful?

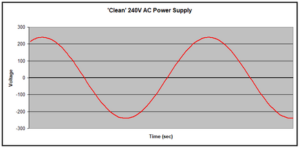

AC (mains) power supply follows a pattern called a sine wave. When it comes to running equipment with sensitive electronics (like inverter machines and computers) power supply with a perfectly clean sine wave is the safest, however in reality this is almost impossible to achieve.

A perfectly ‘clean’ 240V single phase AC sine wave would look something like this:

Mains power is (usually) relatively close to perfect sine power and therefore it rarely poses any problems.

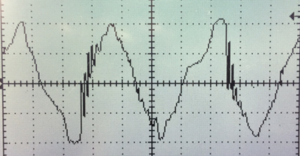

On the other hand, power supply from a portable generator is, by comparison, typically ‘dirty’. The peaks, troughs and cycle frequency will not be consistent even though the average output power may still read 240V on a simple measuring device like a multimeter. Generator power can also be characterized by voltage ‘surges’ (a rise in voltage) and voltage ‘spikes’ (very sudden peaks of excessive voltage).

In a generator, voltage surges and spikes can occur due to several reasons, including:

A typical generator with a high THD over 6% would look something like this. This is NOT a generator you would want to operate your welding equipment, computer, etc. with.

Why are inverter welders vulnerable?

To significantly reduce the size of the transformer and achieve the many advantages that the inverter gives us (reduced size/weight, etc), the input power must be ‘treated’ before it enters the transformer – in other words instead of immediately passing through the transformer, it first passes through sensitive electronic components.

The main components of concern are capacitors. Capacitors are devices which constantly charge and discharge voltages. In an inverter welder, the capacitors will charge at approximately 1.4 times the standard input voltage. So, in the case of 240V power supply they will charge at about 335V. The same will occur in the case of a voltage surge or spike. So, for a 280V surge, they would charge at about 395V which is a voltage increase of 155V. It is this significant fluctuation in working voltage that can damage or destroy electronic components in an inverter welding machine.

Input voltage protection

At SanRex, we recognize that many operators (especially in rural, construction and maintenance industries) have the need to run their welder off a generator.

SanRex machines are specifically designed to protect against a high level of voltage fluctuations and dirty power.

The following features have been incorporated into SanRex machines to ensure optimum protection from power supply fluctuations:

Because of this, SanRex inverters include protection circuitry that protects internal components from dirty power.

Bottom line:

If a SanRex machine is rebooting or showing an error when operating on a generator it is most likely because of dirty power produced by the generator. Our welding machine is protecting itself from the power supplied telling you it will not function on this generator. A generator issue, not a Welding machine issue.