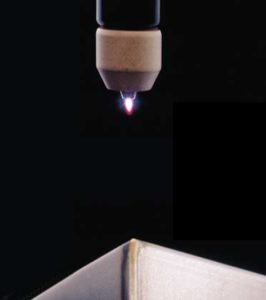

Plasma welding is very similar to TIG Welding as the arc is formed between a pointed tungsten electrode and the work piece. However, by positioning the electrode within the body of the torch, the plasma arc can be separated from the shielding gas envelope. Plasma is then forced through a fine-bore copper nozzle which constricts the arc. Three operating modes can be produced by varying the bore diameter and plasma gas flow rate

Plasma welding is very similar to TIG Welding as the arc is formed between a pointed tungsten electrode and the work piece. However, by positioning the electrode within the body of the torch, the plasma arc can be separated from the shielding gas envelope. Plasma is then forced through a fine-bore copper nozzle which constricts the arc. Three operating modes can be produced by varying the bore diameter and plasma gas flow rate

Microplasma welding – Typical current range from 0.1 – 15A. Microplasma is used for welding thin sheets (down to 0.004” thickness), and wire and mesh sections. The needle-like, stiff arc minimizes arc wander and distortion.

Medium current welding (Melt in Fusion Mode)– Typical current range from 15 – 200A. This is an alternative to conventional TIG. The advantages are deeper penetration (from higher plasma gas flow), greater tolerance to surface contamination including coatings (the electrode is within the body of the torch) and better tolerance to variations in electrode to work piece distance, without significant change in heat input.

Keyhole welding – Typically over 100A. By increasing welding current and plasma gas flow, a very powerful plasma beam is created which can achieve full penetration in a material, as in laser or electron beam welding. During welding, a keyhole is formed which progressively cuts through the metal with the molten weld pool flowing behind to form the weld bead under surface tension forces. This process can be used to weld thicker material (up to 3/8” of stainless steel) in a single pass.

For Ferrous metals the plasma arc is normally operated with a DC, constant current (drooping) characteristic power source. Because its unique operating features are derived from the special torch arrangement and separate plasma and shielding gas flows, a plasma control console can be added on to a conventional TIG power source. Purpose-built plasma systems are also available. For non-Ferrous metals the plasma arc is normally operated with a Variable polarity, constant current (drooping) characteristic power source.

Although the arc is initiated using HF, it is first formed between the electrode and plasma nozzle. This ‘pilot’ arc is held within the body of the torch until required for welding then it is transferred to the work piece. The pilot arc system ensures reliable arc starting and, as the pilot arc is maintained between welds, it obviates the need for HF re-ignition which may cause electrical interference.

The electrode used for the plasma process is tungsten-2% thoria, and the plasma nozzle is copper. The plasma nozzle bore diameter is critical and too small a bore diameter for the current level and plasma gas flow rate will lead to excessive nozzle erosion or even melting.

Normal gas combinations are argon for the plasma gas, with argon or argon plus 2 to 5% hydrogen for the shielding gas. Helium can be used for plasma gas but because it is hotter this reduces the current rating of the nozzle. Helium’s lower mass can also make the keyhole mode more difficult. Helium argon mixtures are used as a shielding gas for materials such as copper.